-

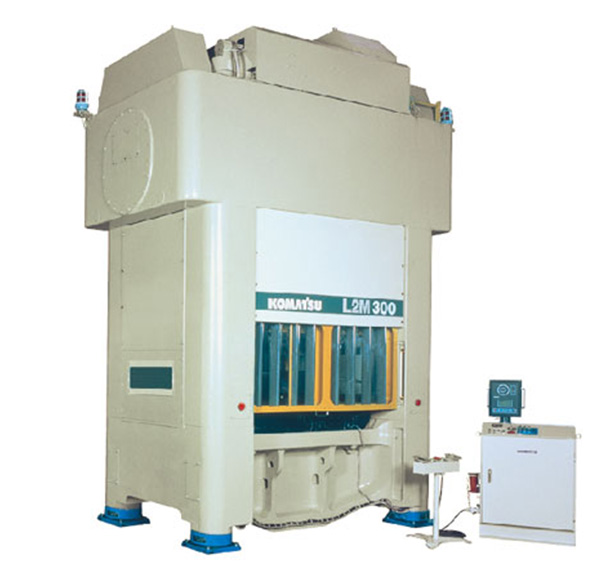

Komatsu Mechanical Presses L2M/E2M series

- Product code: L2M/E2M

-

Progressive press with high rigidity and accuracy.

Mechanical Presses for Progressive Stamping

L2M/E2M series

L(E)2M200 / L(E)2M300 / L(E)2M400 / L(E)2M500

- High rigidity cast steel and tie rods

- Extremely rigid drive and significantly reduced die load

- Heat-balanced circulating lubrication system to minimize heat fluctuation

- Purpose: Progressive

- Frame: Straight

- Point: 2pt

- Capacity: 2000kN

| Model | L(E)2M200 | L(E)2M300 | L(E)2M400 | L(E)2M500 | ||

|---|---|---|---|---|---|---|

| Capacity | kN | 2000 | 3000 | 4000 | 5000 | |

| Slide Stroke | mm | 100 | 125 | 200 | 200 | |

| Max SPM | min-1 | 150 | 120 | 80 | 80 | |

| Die Height | mm | 475 | 550 | 700 | 700 | |

| Slide Adjustment | mm | 100 | 100 | 150 | 150 | |

| Slide | L-R | mm | 1550 | 1850 | 2150 | 2150 |

| F-B | mm | 850 | 900 | 1150 | 1150 | |

| Bolster | L-R | mm | 1550 | 1850 | 2150 | 2150 |

| F-B | mm | 950 | 1000 | 1250 | 1250 | |

High rigidity cast steel and tie rods

With L2M/E2M200, noise and vibration on blanking have been significantly reduced with using the "cast steel frame."And high accuracy forming has been secured by high rigidity of no deformation structure using the "full tie rod structure" and the "front-rear-left-right symmetrical frame."

In addition, they have the following features that improve rigidity and easy-to-use properties.

- Slide inclination has been reduced and anti-eccentric load characteristics has been remarkably improved with the higher rigidity of slide drive and the wider point distance.

- Wide opening on sides easily allows progressive forming of wide coil.

Extremely rigid drive and significantly reduced die load

1. Dynamic balancer

L2M series machines are equipped with the dynamic balancer (suspension) at an ideal location, which minimizes slide deformation by moving counter to the slide.

2. Plunger + plunger guide + eight face long gib

They absorb thrust force and counter to eccentric load. Dynamic accuracy is maintained for a long time to support a longer die life.

3. Hydraulic clutch brake

Emergency stop performance has been greatly improved by 40 percent than previous machines. Inching performance has been also improved for easier die adjustment on preparation.

4. Hydraulic adjust lock system

With a hydraulic driven lock nut structure, clearance on the point part can be made to nil. Since the clearance isn't expanded, high accuracy is maintained for a long time.

Heat-balanced circulating lubrication system to minimize heat fluctuation

Lubrication oil heated in the drive system is circulated through the column to minimize die height variation by offsetting frame extension and drive extension to each other.