-

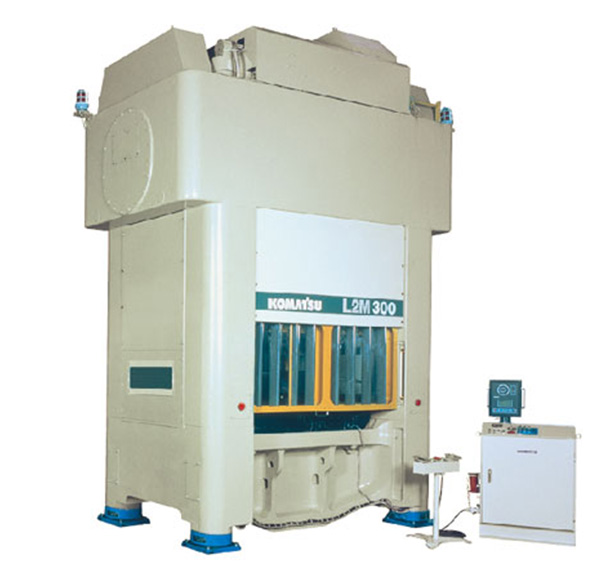

Komatsu Ac Servo Presses H1F-2 / H1F110-2

- Product code: H1F-2 / H1F110-2

-

H1F-2 series

H1F110-2 / H1F150-2 / H1F200-2

Debut: O-frame specification long-awaited with H1F200-2

- Different products with just one of this servo press:

- Simpler motion setting:

- Maintaining product accuracy for a long time

- The same power source capacity with conventional mechanical press

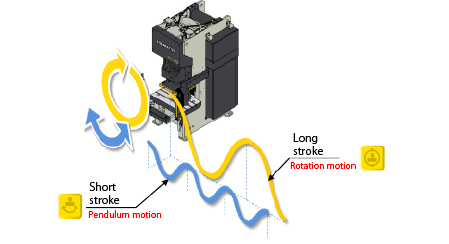

Just one press of ours, having long stroke length of No. 1 among competition and combining with pendulum motion, makes both general-purpose use and high productivity compatible.

With the longer stroke length, production speed is the same or faster than conventional machines! It provide you with wide general-purpose applications.

- Purpose:Precision,General

- Frame:Gap/Straight

- Point:1pt

- Capacity:1100kN〜2000kN

| Model | H1F110-2 | H1F150-2 | H1F200-2 | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Frame Structure | C Frame | O Frame | C Frame | O Frame | C Frame | O Frame | |||||||||||||||||

| Capacity | kN | 1100 | 1500 | 2000 | |||||||||||||||||||

| Slide Stroke | mm | 200 | 250 | 300 | |||||||||||||||||||

| Max SPM | min-1 | 70 | 60 | 50 | |||||||||||||||||||

| Pendulum Slide Stroke | mm | 30〜150 | 30〜200 | 30〜250 | |||||||||||||||||||

| Pendulum Max SPM | min-1 | -77/ St150 | -102/ St80 | -138/ St30 | -79/ St160 | -88/ St120 | -100/ St80 | -62/ St200 | -72/ St160 | -89/ St110 | |||||||||||||

| Die Height | mm | 350(Standard) / 380(Long) | 420(Standard) / 450(Long) | 450(Standard) / 480(Long) | |||||||||||||||||||

| Slide Adjustment | mm | 100 | 120 | ||||||||||||||||||||

| Slide | L-R | mm | 620 | 700 | 700 | 820 | 850 | 1050 | |||||||||||||||

| F-B | mm | 530 | 550 | 650 | |||||||||||||||||||

| Bolster | L-R | mm | 1100 | 900 | 1100(Standard) / 1250(Wide) | 1070 | 1450 | 1200 | |||||||||||||||

| F-B | mm | 680 | 680 | 760 | 840 | ||||||||||||||||||

| Thickness | mm | 150 | 150 | 165 | 180 | ||||||||||||||||||

It has the long stroke length, of No. 1 among competition, to cope with variety of products. Setting at the lowest stroke length to meet the product height with the pendulum motion, high productivity can be achieved. With this servo press of excellent versatility, you can flexibly respond to the market variation.

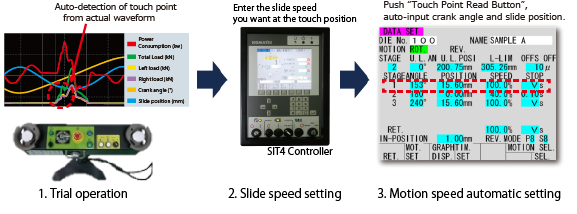

Simpler motion setting:

Are your productivity and forming performance compatible?

For improving forming performance:

It is commonly accepted that low speed forming is suitable to general drawing and bending, and that low speed forming and stop motion at bottom dead center to plate forging and crashing. On the other hand, lower slide speed and stop motion are contradictory to high forming performance and make productivity lower.

For improving productivity:

Moving the slide at the highest speed while not forming, and using the most suitable motion while forming (die touching through finishing) will make increase production speed.

Trial and error motion change:

But generally it is impossible to know momentary starting (die touching) point of forming visually. Trial and error motion setting was necessary for pursuing productivity.

Troublesome motion setting is resolved by our "Optimizing Motion System (OMS)."

Just try forming once and press a button. The die touching point will be recorded. About in one minute.

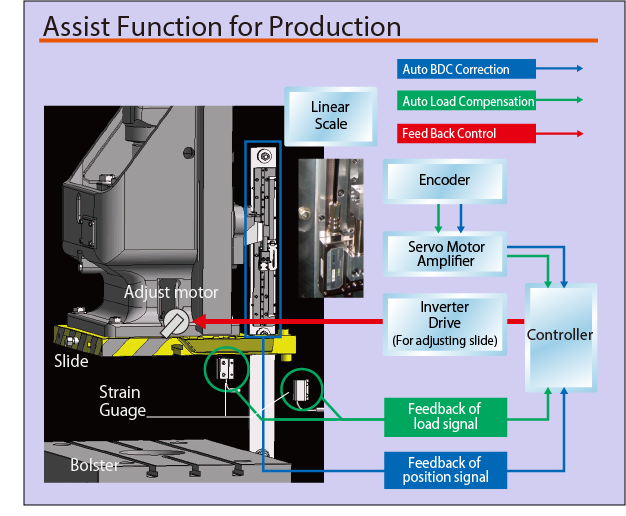

Maintaining product accuracy for a long time

Doesn't product accuracy variate after some time?

Effect of various kinds of heat:

Surrounding temperature change and heat generated in the press/dies make dimensions of the press/dies change, and eventually affect product accuracy. Such effect can be made minimal in a constant temperature room, but cannot be expected in many ordinary production sites.

For stable production of acceptable products:

We suppose, at many production sites, you are taking care, upon experiences, to secure acceptable products by stopping operation to adjust die height periodically and by increasing frequency of sampling inspection.

Based on actual slide position measured by the linear scale and actual forming load measured by the load monitor, slide positions are automatically controlled, with Komatsu's own technology.